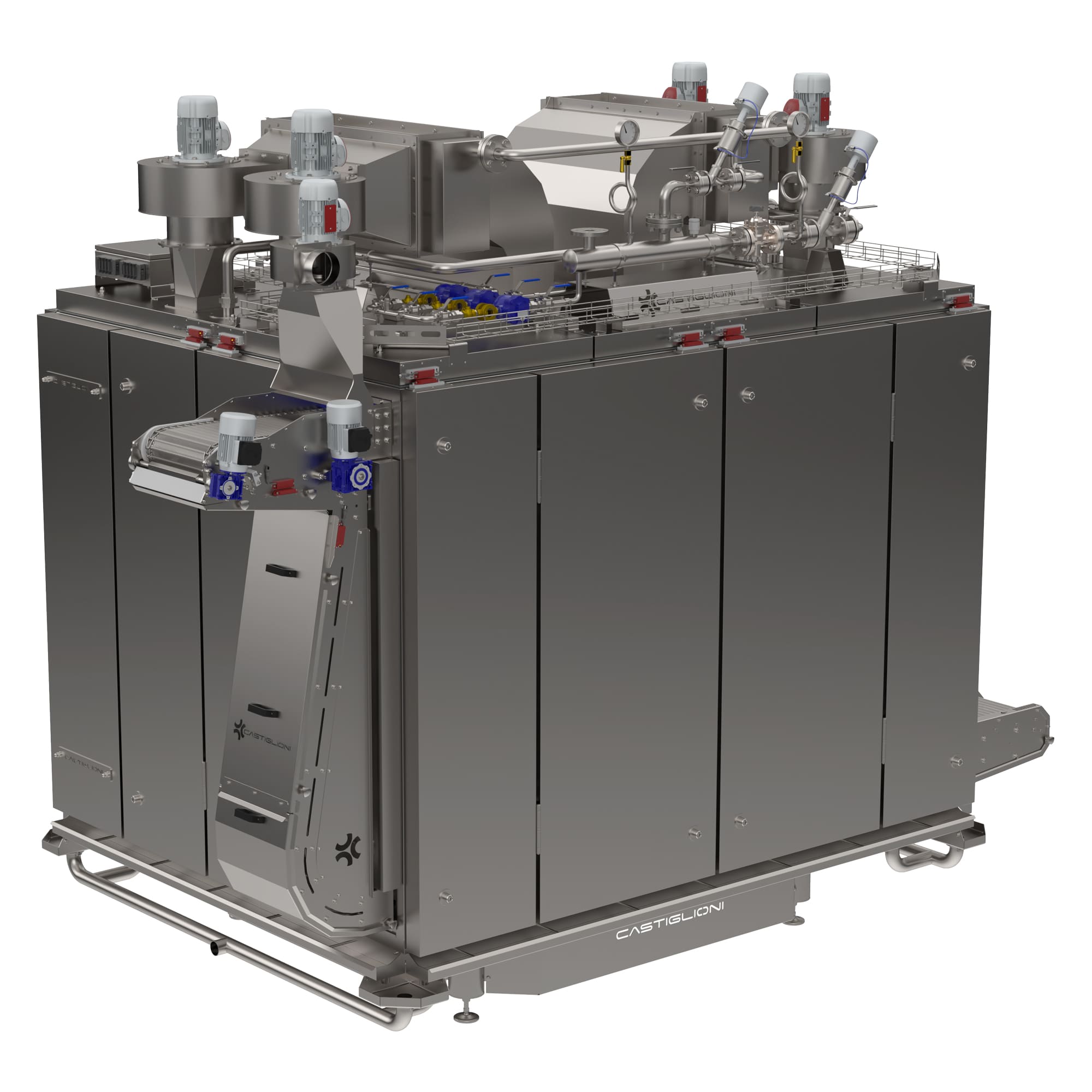

Spiral pasteurizer

Our spiral pasteurisers are suitable for middle and large-sized pasta factories. These machines are designed to improve the production performance and versatility of your line and reduce machine operating costs. These machines are ideal for processing short-cut and filled fresh pasta, but they are so versatile that they can process a wide range of bulk or packed food products.

Spiral pasteuriser and dryer

Model: P13-81-DA

Hourly output: 400 kg/h

Model: P15-115-DA

Hourly output: 900 kg/h

Our spiral pasteuriser provides highly versatile heat treatment for finished products. Moreover, a specially designed internal partition is used to replace the drying process with a hot-air step which maintains product sensory properties unaltered.

Post-packaging spiral pasteuriser

Our spiral pasteuriser is designed to reduce the bacterial load of the products and is useful to pasteurise products packed in pouches or on trays.