Fresh pasta pasteurizers

Fresh pasta pasteurisers are used to reduce the bacterial load of the products in the production of food-grade pasta.

Machines for pasta factories, used for the heat treatment and pasteurisation of fresh pasta and food products. These machines are designed to process fresh pasta, short-cut, long-cut and stuffed. From small craft businesses to industrial-level pasta factories.

Electric belt pasteuriser with dryer

Model: AEN

Hourly output: 20/30 kg/h

Fresh-pasta pasteuriser, ideal for small-sized production batches in craft businesses or small pasta factories. The machine is suitable for pasteurizing short-cut and filled fresh pasta.

Manual electric basket pasteuriser

Model: AEC

Hourly output: 20/30 kg/h

Fresh-pasta pasteuriser, ideal for small-sized production batches in craft businesses or small pasta factories. The machine is suitable for pasteurizing short-cut and filled fresh pasta.

Electric pasteuriser

Model: AE

Hourly output: from 50 kg/h to 300 kg/h

Our fresh-pasta electric pasteuriser is designed for pasteurising food-grade short-cut and filled pasta.

Spiral pasteuriser for fresh pasta

Model : P13-81-DA

Hourly output: 400 kg/h

Model: P15-115-DA

Hourly output: 900 kg/h

Our spiral pasteuriser provides highly versatile heat treatment for finished products. Moreover, a specially designed internal partition is used to replace the drying process with a hot-air step which maintains product sensory properties unaltered.

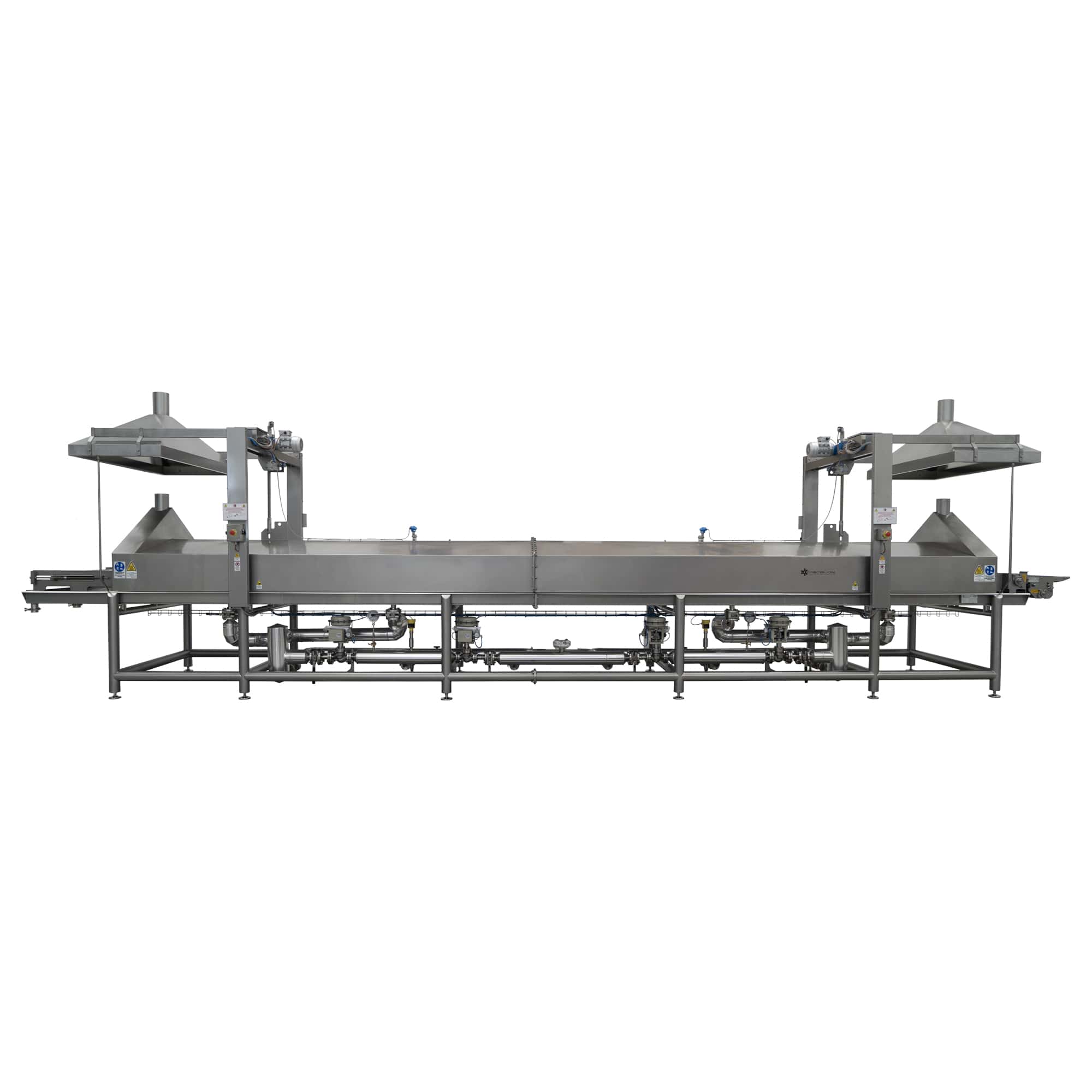

Steam pasteuriser

Model: AV

Hourly output: from 300 kg/h to 2000 kg/h

Our linear steam pasteuriser for fresh pasta is designed for pasteurising food-grade short-cut and filled pasta.

steam pasteuriser with dryer

Model: AV-A

Hourly output: from 300 kg/h to 2000 kg/h

Our linear steam pasteuriser for fresh pasta is designed for pasteurising food-grade short-cut and filled pasta.